Final Production Random Inspection

“Avoid business loss by identifying quality issues before shipment.”

(FPRI) Final Production Random Inspection is an essential element of supply chain management. PSI is also referred to as a Final Random Inspection (FRI). It is done at the end of production, as soon as the tiles are packed in boxes (before palletizing).

WHY DO YOU NEED FINAL PRODUCTION RANDOM INSPECTION (FPRI) ?

Avoid business loss owing return or rework of costly goods. Save time, money and pain by solving issues before shipment. Improve quality by taking immediate corrective actions. Ensure efficient warehouse management with correct packing and labeling.

Protect your brand and reputation.

Monitor your supplier's performance.

This can only begin after production is 100% completed. Once the merchandise is completely packed & ready our highly trained Trade inspector will visit & monitor the quality of your goods.

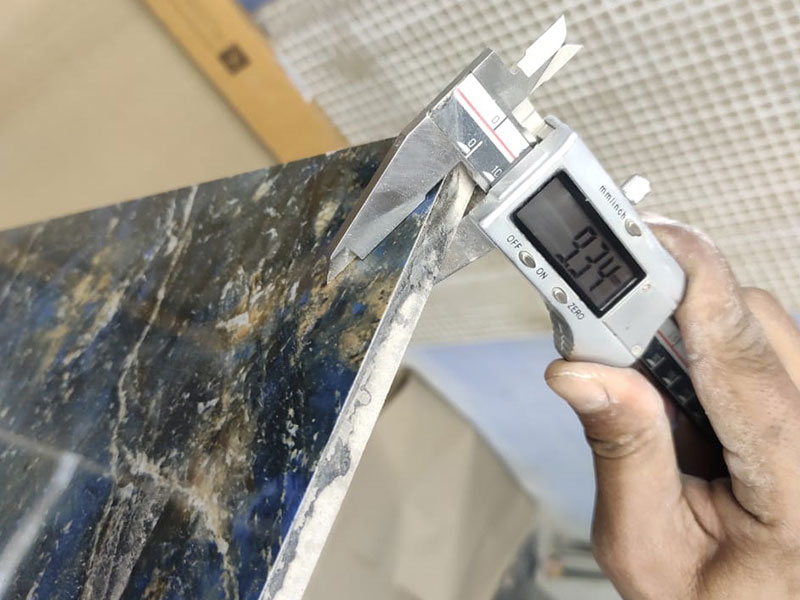

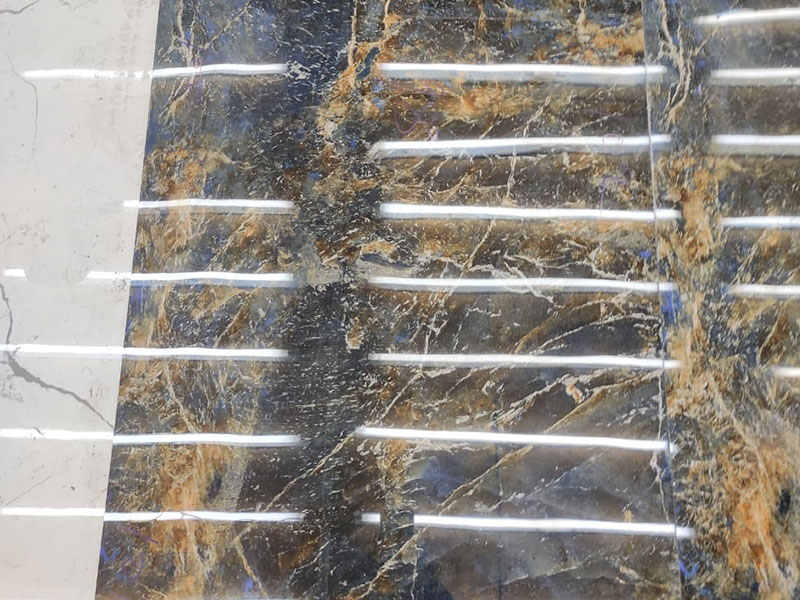

In this inspection, our inspector will conduct the inspection based on a random selection of product pieces according to AQL.

Match the produced quantity with PO quantity. Size ,colour, style & marking check. Product safety. Photo evidence of defects specifying them by critical, major & minor appearance.

Our inspector will issue a detailed report within 24 hours of inspection.